What is defence procurement procedure – Defence procurement procedure encompasses the intricate process of acquiring goods and services for military and defence purposes. This comprehensive guide delves into the various stages, stakeholders, and strategies involved in defence procurement, providing a thorough understanding of its complexities and significance.

Defence procurement plays a critical role in ensuring the operational readiness and effectiveness of armed forces worldwide. It involves a systematic approach to identifying and fulfilling defence requirements, considering factors such as project complexity, budget constraints, and timeframes.

Procurement Process Overview

The defence procurement process is a complex and multi-stage process that involves various stakeholders and follows specific procedures to acquire goods and services for defence purposes.

The key stages of the defence procurement process typically include:

- Requirement Identification and Definition:Identifying and defining the specific needs and requirements for the defence equipment or service.

- Market Research and Supplier Identification:Conducting market research to identify potential suppliers and assessing their capabilities to meet the requirements.

- Request for Proposals (RFP) or Invitation to Bid (ITB):Issuing a formal document outlining the requirements and inviting suppliers to submit proposals or bids.

- Proposal Evaluation and Selection:Evaluating the proposals or bids based on pre-defined criteria, including technical specifications, cost, and delivery timelines.

- Contract Award:Negotiating and finalizing the contract with the selected supplier, outlining the terms and conditions of the procurement.

- Contract Management:Monitoring and managing the contract throughout its duration, ensuring compliance with the agreed-upon terms and conditions.

Roles and Responsibilities of Stakeholders

The defence procurement process involves various stakeholders, each with specific roles and responsibilities:

- End-Users:The military or defence forces who will use the procured equipment or services and provide input on their specific requirements.

- Procurement Agency:The government agency or department responsible for managing the procurement process, including issuing RFPs, evaluating proposals, and awarding contracts.

- Suppliers:Companies or organizations that provide the goods or services required by the defence forces.

- Contracting Authority:The individual or entity within the procurement agency authorized to enter into contracts on behalf of the government.

- Financial Auditors:Responsible for reviewing and auditing the procurement process to ensure compliance with financial regulations and proper use of public funds.

Requirement Definition

Requirement definition is the process of identifying and defining the needs of a defence procurement project. It involves engaging with stakeholders, conducting market research, and performing gap analysis to determine the specific capabilities and specifications required for the project. This process is critical for ensuring that the procurement project meets the operational needs of the defence force and delivers the desired outcomes.

Stakeholder Engagement

Stakeholder engagement is a crucial aspect of requirement definition. It involves identifying and engaging with all stakeholders who have an interest in or will be affected by the procurement project. This may include users, operators, maintainers, suppliers, and regulatory authorities.

The goal of stakeholder engagement is to gather their input, understand their needs, and ensure that their interests are considered in the requirements definition process.

Market Research

Market research is another important element of requirement definition. It involves gathering information about the existing and emerging technologies, products, and services that can meet the needs of the procurement project. This research helps to identify potential suppliers, assess the feasibility of different solutions, and inform the development of the requirements specifications.

Gap Analysis

Gap analysis is a technique used to identify the difference between the current capabilities and the desired capabilities for the procurement project. This analysis helps to determine the specific areas where improvements are needed and provides a basis for developing the requirements specifications.

User Needs Analysis

User needs analysis is a critical step in requirement definition. It involves gathering and analyzing the needs of the users who will be operating and maintaining the procured equipment or system. This analysis can be conducted using a variety of techniques, such as interviews, surveys, and focus groups.

The goal is to understand the users’ tasks, workflows, and expectations, and to translate these needs into specific requirements.

Requirements Specifications

Requirements specifications are the formal documents that define the specific capabilities and specifications required for the procurement project. These specifications should be clear, concise, and verifiable. They should also be structured in a way that allows for easy comparison of different solutions and the evaluation of their ability to meet the requirements.

Trade-offs and Risk Assessment

Requirement definition often involves making trade-offs between different requirements. For example, a requirement for increased performance may come at the expense of cost or schedule. It is important to carefully consider the trade-offs involved and to assess the risks associated with each decision.

This risk assessment should consider both the likelihood and the impact of potential risks, and it should inform the decision-making process.

Summary of Key Steps in Requirement Definition

The key steps in the requirement definition process can be summarized as follows:

- Identify and engage stakeholders

- Conduct market research

- Perform gap analysis

- Conduct user needs analysis

- Develop requirements specifications

- Consider trade-offs and assess risks

Provide a detailed explanation of how market research is conducted in defence procurement.

Market research is a critical element of defence procurement, as it provides the necessary information to make informed decisions about the acquisition of goods and services. The process of conducting market research in defence procurement typically involves the following steps:

- Define the research objectives.The first step is to clearly define the objectives of the market research. This will help to ensure that the research is focused and that the data collected is relevant to the decision-making process.

- Identify the target audience.The next step is to identify the target audience for the market research. This will include potential suppliers, industry experts, and other stakeholders.

- Develop a research plan.Once the target audience has been identified, a research plan should be developed. This plan should Artikel the methods that will be used to collect data, the timeline for the research, and the budget for the project.

- Collect data.The next step is to collect data from the target audience. This can be done through a variety of methods, such as surveys, interviews, and focus groups.

- Analyze the data.Once the data has been collected, it should be analyzed to identify trends and patterns. This analysis will help to inform the decision-making process.

- Develop recommendations.Based on the analysis of the data, recommendations should be developed for the acquisition of goods and services. These recommendations should be based on the research findings and should be tailored to the specific needs of the defence organization.

Best practices for identifying and evaluating potential suppliers

There are a number of best practices that can be followed when identifying and evaluating potential suppliers. These include:

- Use a variety of sources to identify potential suppliers.This will help to ensure that the organization has a comprehensive list of potential suppliers to choose from.

- Develop a set of evaluation criteria.This will help to ensure that the organization is evaluating potential suppliers on a consistent basis.

- Conduct due diligence on potential suppliers.This will help to ensure that the organization is aware of any potential risks associated with doing business with a particular supplier.

- Negotiate favorable terms and conditions.This will help to ensure that the organization is getting the best possible value for its money.

The role of market research in developing procurement strategies

Market research plays a critical role in developing procurement strategies. By providing information about the market, potential suppliers, and the needs of the organization, market research can help to ensure that the organization develops a procurement strategy that is aligned with its objectives.

Different methods used to collect market research data

There are a variety of methods that can be used to collect market research data. These include:

- Surveys.Surveys are a quantitative method of collecting data that can be used to gather information from a large number of respondents.

- Interviews.Interviews are a qualitative method of collecting data that can be used to gather in-depth information from a small number of respondents.

- Focus groups.Focus groups are a qualitative method of collecting data that can be used to gather information from a small group of respondents.

- Secondary research.Secondary research involves the use of existing data to conduct market research. This data can be found in a variety of sources, such as industry reports, government publications, and academic journals.

Examples of how market research has been used to improve defence procurement outcomes

There are a number of examples of how market research has been used to improve defence procurement outcomes. These include:

- The US Department of Defense (DoD) used market research to identify potential suppliers for a new combat vehicle.The research helped the DoD to develop a list of qualified suppliers and to negotiate favorable terms and conditions for the contract.

- The UK Ministry of Defence (MoD) used market research to develop a procurement strategy for a new aircraft carrier.The research helped the MoD to understand the market for aircraft carriers and to identify the best suppliers for the project.

- The Australian Department of Defence (DoD) used market research to evaluate the performance of a new weapons system.The research helped the DoD to identify areas where the system could be improved and to make recommendations for future procurement decisions.

Table summarizing the key steps involved in conducting market research for defence procurement

| Step | Description |

|---|---|

| 1 | Define the research objectives |

| 2 | Identify the target audience |

| 3 | Develop a research plan |

| 4 | Collect data |

| 5 | Analyze the data |

| 6 | Develop recommendations |

Market research is a critical element of defence procurement, as it provides the necessary information to make informed decisions about the acquisition of goods and services.

– Jane’s Defence Weekly

Supplier Selection: What Is Defence Procurement Procedure

Supplier selection is a crucial phase in defence procurement as it determines the quality, reliability, and cost-effectiveness of the acquired goods or services. The process involves evaluating and selecting suppliers based on predefined criteria to ensure that they meet the specific requirements of the defence organization.

Key criteria considered during supplier selection include capability, capacity, cost, quality, reliability, and security. Capability refers to the supplier’s technical expertise and experience in delivering the required products or services. Capacity assesses the supplier’s ability to meet the required production or service levels within the specified time frame.

Cost is a significant factor, but it should be evaluated in conjunction with other criteria to avoid compromising quality or reliability.

Request for Proposals (RFP)

RFPs are formal documents that Artikel the specific requirements of the defence organization and invite potential suppliers to submit proposals. RFPs typically include detailed specifications, delivery timelines, quality standards, and evaluation criteria.

Supplier Questionnaires

Supplier questionnaires are used to gather information about a supplier’s capabilities, experience, and financial stability. They can help identify potential risks and areas for further due diligence.

Site Visits

Site visits allow defence procurement teams to assess a supplier’s facilities, production processes, and quality control measures firsthand. This provides valuable insights into the supplier’s operations and helps verify the information provided in the RFP response.

Reference Checks

Reference checks involve contacting previous customers of the supplier to obtain feedback on their performance, quality of products or services, and reliability. This helps assess the supplier’s track record and identify any potential issues.

Risk Assessment and Due Diligence

Risk assessment and due diligence are essential components of supplier selection. Risk assessment identifies potential risks associated with a supplier, such as financial instability, quality issues, or security concerns. Due diligence involves conducting thorough investigations to mitigate these risks and ensure the supplier meets the required standards.

Contracts

Once a supplier is selected, a contract is established to define the terms and conditions of the procurement. The contract should clearly Artikel the scope of work, delivery timelines, quality standards, payment terms, and dispute resolution mechanisms.

Contract Negotiation

Contract negotiation is a critical phase in defence procurement, as it establishes the terms and conditions of the agreement between the procuring entity and the supplier. The negotiation process involves both parties working together to reach a mutually acceptable outcome that meets the requirements of the procurement.

The key terms and conditions that are typically included in defence procurement contracts include:

- Scope of work:This defines the specific goods or services to be provided by the supplier.

- Price and payment terms:This specifies the total cost of the contract and the payment schedule.

- Delivery schedule:This Artikels the timeline for the delivery of goods or services.

- Quality standards:This establishes the minimum quality standards that the goods or services must meet.

- Warranties and guarantees:This provides assurance that the goods or services will perform as expected.

- Intellectual property rights:This determines who owns the intellectual property rights to the goods or services developed under the contract.

- Termination clauses:This specifies the conditions under which either party can terminate the contract.

The negotiation process typically begins with the procuring entity issuing a request for proposal (RFP) to potential suppliers. The RFP Artikels the requirements of the procurement and provides instructions for submitting proposals. Suppliers then submit their proposals, which are evaluated by the procuring entity based on a set of criteria.

The procuring entity may then invite the shortlisted suppliers to participate in negotiations. The negotiations are typically conducted in a series of meetings, where the parties discuss the terms and conditions of the contract. The goal of the negotiations is to reach a mutually acceptable agreement that meets the needs of both parties.

Once the negotiations are complete, the procuring entity and the supplier will sign a contract. The contract is a legally binding agreement that sets out the terms and conditions of the procurement.

Contract Management

Effective contract management is crucial in defence procurement, ensuring the successful execution of contracts and the delivery of required goods and services. It brings numerous benefits to stakeholders and the organization as a whole, including:

- Ensuring compliance with legal and regulatory requirements

- Protecting the interests of all parties involved

- Minimizing risks and avoiding costly disputes

- Facilitating timely delivery of quality products and services

- Building and maintaining strong supplier relationships

Key Responsibilities of Contract Management

Contract management involves several key responsibilities:

Contract Negotiation and Drafting

Negotiating and drafting clear and comprehensive contracts that protect the interests of all parties. This includes defining the scope of work, payment terms, delivery schedules, and performance standards.

Contract Administration and Monitoring

Monitoring contract performance, tracking progress, and ensuring compliance with contractual obligations. This involves regular communication with suppliers, reviewing deliverables, and addressing any issues or changes that may arise.

Contract Compliance and Enforcement

Enforcing contract terms and taking appropriate action in case of non-compliance. This may include issuing warnings, imposing penalties, or even terminating the contract if necessary.

Challenges in Defence Contract Management

Defence procurement contracts are often complex and lengthy, involving multiple stakeholders with diverse interests. Additionally, the rapidly changing technology and regulatory landscape can pose challenges to contract management.

Specific challenges include:

- Interpreting and managing complex contractual language

- Coordinating and managing multiple stakeholders with conflicting interests

- Keeping up with rapidly evolving technology and regulatory changes

- Managing risks associated with long-term contracts

Recommendations for Improving Contract Management

To overcome these challenges and improve contract management practices, the following recommendations are suggested:

- Utilizing technology to streamline processes and improve communication

- Establishing clear communication channels and protocols

- Implementing robust risk management strategies

- Providing regular training to contract managers

- Fostering collaboration and open communication among stakeholders

Conclusion

Effective contract management is essential for successful defence procurement. It ensures compliance, protects interests, minimizes risks, and facilitates timely delivery of quality products and services. By addressing the challenges and implementing best practices, organizations can enhance their contract management capabilities and achieve greater success in defence procurement.

Risk Management

Risk management is a crucial aspect of defence procurement, as it involves managing uncertainties and potential threats that can impact the successful execution of procurement projects. The key risks associated with defence procurement include:

- Schedule delays:Unforeseen circumstances, such as supply chain disruptions or technical issues, can lead to delays in project completion.

- Cost overruns:Changes in project requirements, unexpected expenses, or inflation can result in increased procurement costs.

- Performance failures:Equipment or systems may not meet the required performance specifications, leading to operational challenges.

- Security breaches:Procurement processes may expose sensitive information to unauthorized parties, compromising national security.

- Ethical and legal concerns:Defence procurement involves significant public funds and must adhere to ethical and legal standards to avoid corruption or misconduct.

To mitigate these risks, defence procurement organizations employ various strategies and techniques, including:

- Risk identification and assessment:Identifying potential risks and evaluating their likelihood and impact on project outcomes.

- Risk mitigation planning:Developing strategies to reduce the probability and impact of identified risks.

- Risk monitoring and control:Regularly monitoring risks and implementing control measures to minimize their effects.

- Contingency planning:Establishing backup plans and alternative solutions to address unexpected events.

- Stakeholder engagement:Involving stakeholders in risk management to ensure transparency and accountability.

Effective risk management in defence procurement ensures that projects are executed efficiently, within budget, and in accordance with operational requirements. It also protects national security and maintains public trust in the procurement process.

Quality Assurance

Quality assurance is a critical aspect of defence procurement, ensuring the safety, reliability, and cost-effectiveness of defence products. It involves a systematic process of monitoring and evaluating products and services to ensure they meet specified requirements.The quality assurance process in defence procurement begins with the definition of quality requirements during the requirement definition phase.

These requirements are based on the intended use of the product and the specific operational environment in which it will be deployed. Once the requirements are defined, a quality assurance plan is developed to Artikel the specific processes and procedures that will be used to ensure product quality.Testing and inspection are essential components of quality assurance in defence procurement.

Testing involves subjecting products to controlled conditions to evaluate their performance and identify any defects. Inspection involves examining products to verify their conformance to specified requirements. Various testing and inspection methods are used in defence procurement, including:

Functional testing

Evaluates the product’s ability to perform its intended functions.

Environmental testing

Assesses the product’s ability to withstand various environmental conditions, such as extreme temperatures, humidity, and vibration.

Defence procurement procedure involves the acquisition of goods and services for defence purposes. It encompasses the planning, budgeting, and contracting processes. Understanding the intricacies of defence procurement can be challenging, but grasping the concept of utility bills, such as what’s considered a utility bill , can provide valuable insights into the complexities of defence procurement procedures.

Safety testing

Verifies that the product meets safety standards and poses no risk to users.

Non-destructive testing

Examines products without causing damage, using techniques such as radiography and ultrasonic testing.Testing and inspection have played a crucial role in identifying and correcting defects in defence products. For example, in the development of the F-35 fighter jet, extensive testing and inspection helped identify and correct defects in the aircraft’s flight control system, preventing potential safety hazards.Quality assurance is essential for ensuring the safety and reliability of defence products.

By verifying that products meet specified requirements, quality assurance helps prevent defects that could lead to accidents or equipment failures. This contributes to the safety of military personnel and the effectiveness of defence operations.Quality assurance also plays a vital role in reducing the cost of defence procurement.

By identifying and correcting defects early in the procurement process, quality assurance helps prevent costly rework and delays. It also helps ensure that products are designed and manufactured to meet specific requirements, reducing the need for expensive modifications or replacements later on.However, quality assurance in defence procurement faces several challenges.

These include:

The complexity of defence products

Defence products are often highly complex, making it difficult to define and verify quality requirements.

Defence procurement procedure involves the acquisition of goods and services for military use. If you are facing issues with your Mac’s storage, you can refer to where is disk utility on a mac to locate the Disk Utility application. Disk Utility can help you manage and repair your Mac’s storage.

Defence procurement procedure ensures that the military has the necessary resources to carry out its mission effectively.

The need for rapid procurement

In times of conflict or emergency, defence products may need to be procured quickly, which can compromise quality assurance processes.

The lack of standardized quality assurance procedures

There is a lack of standardized quality assurance procedures across different defence organizations, which can lead to inconsistencies in product quality.Despite these challenges, there are opportunities for improving quality assurance in defence procurement. These include:

Investing in advanced testing and inspection technologies

Advanced technologies can improve the accuracy and efficiency of testing and inspection, reducing the risk of defects.

Establishing standardized quality assurance procedures

Standardized procedures can ensure consistency in quality assurance practices and improve product quality.

Promoting a culture of quality

A culture of quality within defence organizations can encourage employees to prioritize quality and identify and correct defects proactively.By addressing these challenges and implementing these opportunities, defence organizations can improve quality assurance and ensure the safety, reliability, and cost-effectiveness of defence products.

Logistics and Distribution

Logistics and distribution play a crucial role in defence procurement, ensuring the timely and efficient delivery of critical supplies and equipment to military forces. The complex nature of defence procurement poses unique challenges in logistics and distribution, demanding innovative strategies and meticulous execution.

Logistics and Distribution Challenges

Defence procurement involves the acquisition of a wide range of items, from small components to large-scale systems, each with its specific transportation and storage requirements. The global nature of defence procurement further complicates logistics, with suppliers located across different regions and time zones.

Moreover, defence procurement often operates under tight deadlines and strict security protocols. The timely delivery of supplies is paramount to ensure operational readiness and mission success. At the same time, the sensitive nature of defence equipment necessitates robust security measures throughout the logistics and distribution process.

Mitigation Strategies

To overcome these challenges, defence procurement agencies employ a range of strategies and techniques. These include:

- Centralized procurement:Consolidating procurement activities under a single authority improves coordination and efficiency in logistics and distribution.

- Long-term contracts:Establishing long-term contracts with suppliers allows for better planning and optimization of logistics and distribution.

- Supplier collaboration:Engaging with suppliers early in the procurement process ensures their understanding of logistics requirements and facilitates timely delivery.

- Robust transportation and storage systems:Utilizing reliable transportation networks and secure storage facilities minimizes delays and ensures the integrity of supplies.

li> Advanced technology:Employing tracking systems, data analytics, and automation tools enhances visibility and efficiency in logistics and distribution.

| Challenge | Mitigation Strategy |

|---|---|

| Global supply chain | Long-term contracts, supplier collaboration |

| Tight deadlines | Centralized procurement, robust transportation systems |

| Security concerns | Secure storage facilities, tracking systems |

| Diverse item types | Customized transportation and storage solutions |

| Limited infrastructure in operational areas | Advanced technology, contingency planning |

Logistics and Distribution Process

The logistics and distribution process in defence procurement typically involves the following steps:

- Planning:Defining logistics requirements, selecting suppliers, and establishing transportation and storage arrangements.

- Procurement:Placing orders with suppliers and coordinating delivery schedules.

- Transportation:Moving supplies from suppliers to designated storage facilities or directly to operational areas.

- Storage:Maintaining supplies in secure and environmentally controlled facilities.

- Distribution:Delivering supplies to military forces in the field or at designated locations.

- Tracking and monitoring:Monitoring the progress of shipments and ensuring timely delivery.

A flowchart illustrating the logistics and distribution process for defence procurement is provided below:

[Image of a flowchart depicting the logistics and distribution process for defence procurement]

Best Practices for Logistics and Distribution in Defence Procurement

To ensure effective logistics and distribution in defence procurement, the following best practices are recommended:

- Establish clear logistics requirements:Define specific logistics needs, including delivery timelines, security protocols, and environmental conditions.

- Collaborate with suppliers:Engage with suppliers early in the procurement process to understand their capabilities and develop tailored logistics solutions.

- Optimize transportation and storage:Utilize reliable transportation networks, secure storage facilities, and tracking systems to ensure timely and secure delivery.

- Leverage technology:Employ advanced technology, such as data analytics and automation tools, to enhance visibility and efficiency in logistics and distribution.

- Conduct regular reviews and assessments:Regularly evaluate the effectiveness of logistics and distribution processes and make necessary adjustments to improve performance.

Performance Monitoring

Performance monitoring is crucial in defence procurement to ensure that suppliers meet the agreed-upon requirements and deliver the expected outcomes. It helps identify potential issues early on, enabling timely corrective actions to maintain project timelines and objectives.

Various metrics and techniques are employed to assess supplier performance, including:

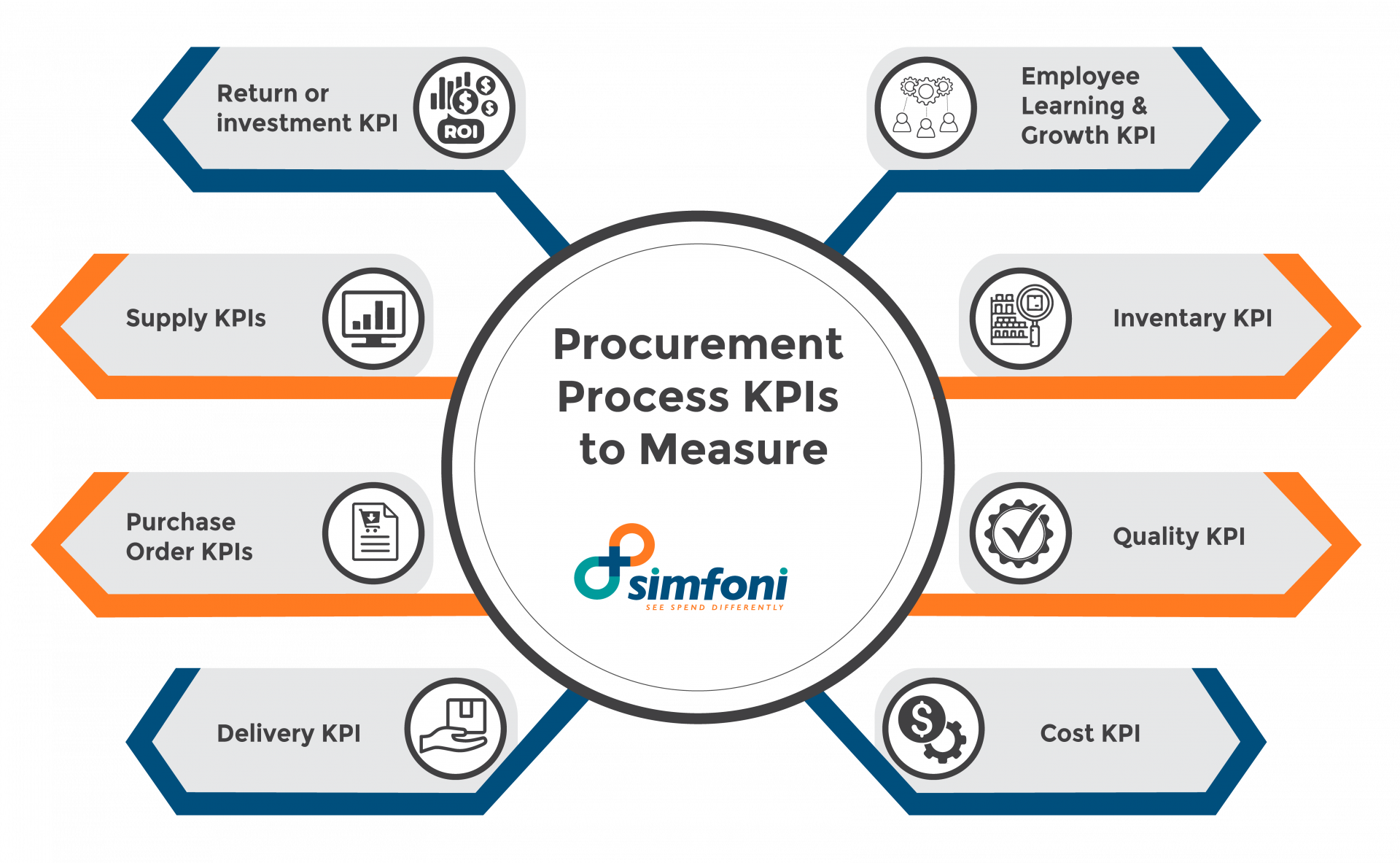

Key Performance Indicators (KPIs)

- Delivery timelines and adherence to schedules

- Product quality and adherence to specifications

- Cost control and adherence to budget

- Responsiveness to changes and flexibility

- Supplier reliability and adherence to contractual obligations

Data Analysis and Reporting

Regular data collection and analysis provide insights into supplier performance. Reports are generated to track progress, identify trends, and highlight areas for improvement.

Supplier Audits and Inspections, What is defence procurement procedure

Audits and inspections are conducted to verify supplier capabilities, processes, and adherence to quality standards. These assessments help identify potential risks and ensure compliance with contractual requirements.

Feedback and Reviews

Feedback from end-users and stakeholders is gathered to evaluate supplier performance from a practical perspective. This feedback is used to make informed decisions about supplier retention and improvement.

Corrective Actions and Improvement Plans

When performance issues are identified, corrective actions are implemented to address the root causes. Suppliers may be required to develop improvement plans to enhance their performance and meet the required standards.

Ethics and Compliance

Ethics and compliance are of utmost importance in defence procurement, as they ensure that the process is fair, transparent, and free from corruption. Governments and defence organizations have established strict regulations and guidelines to govern the procurement process and ensure ethical conduct.

These regulations typically cover aspects such as conflict of interest, bribery, and fraud. They require defence organizations to establish clear policies and procedures to prevent and detect unethical behavior. Additionally, defence organizations are often subject to external audits and oversight to ensure compliance with these regulations.

Innovation and Technology

Innovation and technological advancements play a crucial role in defence procurement, enabling armed forces to maintain their competitive edge and respond effectively to evolving threats. These advancements drive the development of cutting-edge weapons systems, enhance operational capabilities, and improve overall defence preparedness.

Strategies and Techniques

To promote innovation and technological advancements in defence procurement, various strategies and techniques are employed:

- Research and Development (R&D) Funding:Governments allocate significant funds to support R&D initiatives, fostering innovation and the development of new technologies.

- Collaborative Partnerships:Defence organizations collaborate with industry, academia, and research institutions to leverage expertise and drive innovation. These partnerships facilitate the exchange of ideas, cross-fertilization of knowledge, and the development of novel solutions.

- Innovation Challenges and Competitions:Defence agencies organize challenges and competitions to encourage industry and academia to develop innovative solutions for specific defence-related problems. These initiatives foster a competitive environment that stimulates creativity and drives technological breakthroughs.

- Technology Transfer:Defence organizations establish mechanisms to transfer technologies developed for military applications to the civilian sector, promoting economic growth and technological advancements in both domains.

- Dual-Use Technologies:Defence procurement often involves the acquisition of dual-use technologies, which have both military and civilian applications. This approach leverages commercial advancements and reduces procurement costs while supporting the development of innovative solutions.

Case Studies and Best Practices

Successful defence procurement projects provide valuable insights into effective strategies and best practices. Case studies and lessons learned can help stakeholders improve future procurement processes, mitigate risks, and achieve desired outcomes.

Case Studies

- Project Name:F-35 Joint Strike Fighter Program (USA)

- Project Type:Acquisition of advanced multirole fighter aircraft

- Key Challenges:Cost overruns, technical complexities, international collaboration

- Key Success Factors:Strong leadership, rigorous requirements definition, effective risk management

- Project Name:Type 26 Global Combat Ship Program (UK)

- Project Type:Acquisition of advanced anti-submarine warfare frigates

- Key Challenges:Design and production complexities, budget constraints

- Key Success Factors:Innovative procurement approach, early supplier involvement, robust quality assurance

Best Practices

- Early Supplier Involvement:Engaging suppliers early in the procurement process fosters collaboration and reduces risks.

- Clear and Comprehensive Requirements:Well-defined requirements ensure that the procured solution meets the operational needs.

- Effective Risk Management:Identifying and mitigating risks throughout the procurement process helps prevent delays and cost overruns.

- Continuous Performance Monitoring:Tracking performance against agreed metrics allows for timely adjustments and improvement.

Common Challenges and Solutions

| Challenge | Potential Solution |

|---|---|

| Cost overruns | Rigorous cost estimation, effective cost control measures |

| Technical complexities | Early supplier involvement, phased procurement approach |

| Supplier performance issues | Supplier evaluation, performance monitoring, contingency plans |

Quotes

“Early supplier involvement was crucial in identifying and mitigating potential risks, leading to a more successful procurement outcome.”

Project Manager, F-35 Joint Strike Fighter Program

“Clear and comprehensive requirements ensured that the procured solution met our operational needs precisely.”

Senior Naval Officer, Type 26 Global Combat Ship Program

Essential FAQs

What are the key stages of the defence procurement process?

The key stages of the defence procurement process typically include requirement definition, acquisition strategy development, supplier selection, contract negotiation, contract management, performance monitoring, and continuous improvement.

What are the different types of acquisition strategies in defence procurement?

Common acquisition strategies in defence procurement include open tendering, selective tendering, single-source procurement, and commercial off-the-shelf (COTS) procurement.

How is risk assessed and mitigated in defence procurement?

Risk assessment in defence procurement involves identifying potential risks associated with suppliers, contracts, and project execution. Mitigation strategies may include risk transfer, risk avoidance, and risk reduction measures.

Whitney Morris is a renowned author with a passion for military history and strategic analysis. Born in Jakarta, Indonesia, Defense developed a deep fascination for warfare and national defense from a young age. His unwavering interest in military strategy, combined with his natural storytelling ability, has earned him a reputation as an engaging and insightful writer in the field.